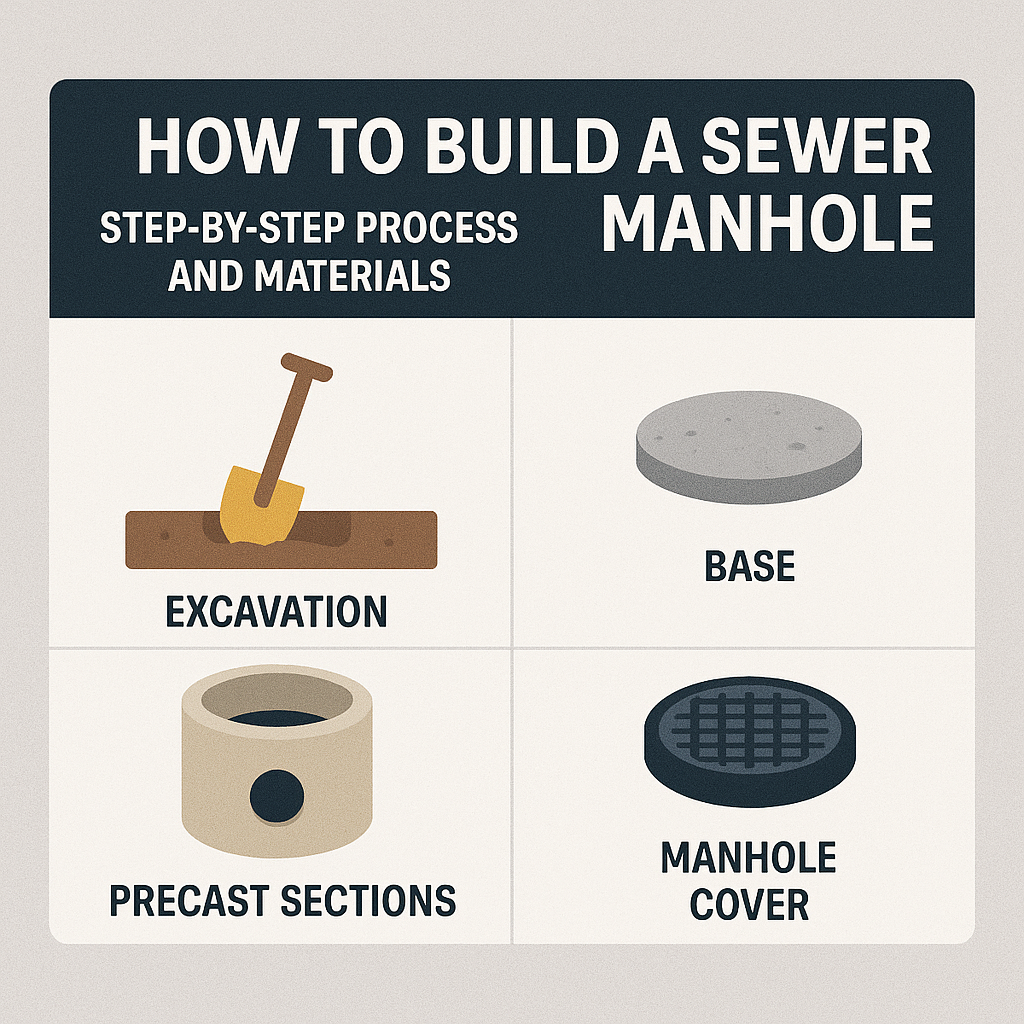

How to Build a Sewer Manhole – Step-by-Step Process and Materials

Sewer manholes are critical infrastructure components, providing access for inspection, cleaning, and maintenance of underground drainage systems. Whether you’re planning a small-scale residential installation or part of a larger civil engineering project, this guide will walk you through the process of constructing a durable and functional manhole.

Why Proper Manhole Construction Matters

Manholes allow easy access to sewer lines, facilitate ventilation, and help in troubleshooting blockages or damage. Poor construction can lead to leaks, ground subsidence, or safety hazards.

Materials Needed

Before starting the construction, gather all required materials. These may vary based on your project scale and local regulations.

-

Concrete rings (prefabricated or cast on-site)

-

Base slab (reinforced concrete)

-

Manhole cover with frame (cast iron or concrete)

-

Rebar (for reinforcement)

-

PVC or concrete sewer pipes

-

Cement, sand, gravel (for concrete mix)

-

Mortar or sealing compound

-

Steps (metal rungs or ladders if deep)

Tools Required

-

Concrete mixer

-

Shovel

-

Trowel

-

Level

-

Measuring tape

-

Rebar bender (optional)

-

Safety equipment (gloves, boots, helmet)

Step-by-Step Construction Process

1. Excavation

Dig a pit based on the depth and diameter required. Allow extra space for working around the structure. Typical depth ranges from 1.5m to 3m.

2. Base Slab Installation

Prepare a reinforced concrete slab at the bottom of the excavation. This serves as the foundation and prevents settlement. Let it cure properly.

3. Position Inlet and Outlet Pipes

Install sewer pipes with the correct slope (typically 2% or 2 cm per meter). Ensure they align with the future channel inside the manhole.

4. Build or Place Concrete Rings

Stack precast concrete rings or cast in-situ walls using formwork. Each ring must be sealed properly with mortar or bitumen to prevent infiltration.

5. Construct Channel (Benching)

Inside the manhole, build a U-shaped flow channel (invert) using cement mortar. This guides sewage flow from the inlet to the outlet.

6. Install Manhole Steps

If the manhole is deeper than 1.2m, install access steps every 30cm on the inner wall.

7. Backfilling and Compaction

After completing the manhole structure, backfill the surrounding soil in layers and compact thoroughly to avoid future settlement.

8. Install Cover and Frame

Position the manhole frame at ground level. Secure the cover to protect the manhole and provide access.

Important Tips

-

Waterproofing: Use sealants to prevent groundwater intrusion.

-

Ventilation: Consider vents for deeper systems.

-

Compliance: Always follow local construction codes and environmental standards.

Common Use Cases

-

Residential drainage networks

-

Stormwater systems

-

Municipal sewer systems

-

Industrial wastewater pipelines

Conclusion

Constructing a sewer manhole requires precision, proper materials, and adherence to safety and engineering standards. This guide offers a foundational understanding, but always consult local building codes or professionals when necessary.